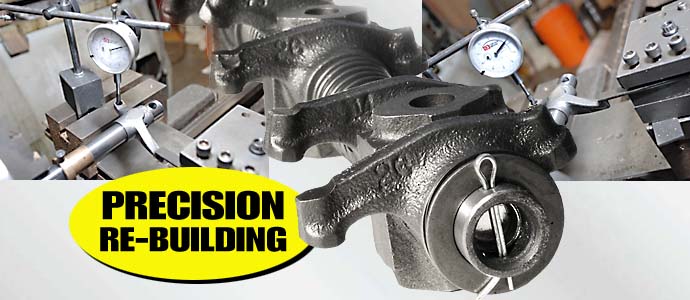

RE-BUILDING PROCESS -

Rocker Arms Unlimited

ROCKER ARMS - After the rocker arms are cleaned we tumble them to reduce any stress risers that may have been created over the years. The rocker arms are bored out and bronze bushings are made to match the bore of the rocker arms and honed to match the diameter of the hard chrome plated shaft. Not all rocker arms get bushed, if they are stamp steel or don't have enough thickness we don't bore the arms and hard chrome plate the shafts. In addition, some motors just don't need to have bushed rocker arms.

SHAFTS - Typically we centerless grind the shafts down, hard chrome plate the shafts, and centerless ground the shaft to the correct shaft size. Each shaft has 4-5 thousandths of hard chrome on the sides for a total of 8-10 thousandths of hard chrome. Not all shafts get chroming, if the rockers are stamped steel, we cannot hard chrome plate the shafts.

STANDS - Through the years of rebuilding rocker arms we have stocked many stands. Although it may not be shown on the site, if we rebuild it, we have the parts for it.

SCREWS - We have both new and used screws for the adjustable assemblies. Call if you broke an adjustment screw, we might just have what you are looking for.

SPECIFIC PARTS - Give us a call, we might have what you are looking for, we have an 8,000 square foot building with lots of pieces and parts that we have acquired over 40 years.